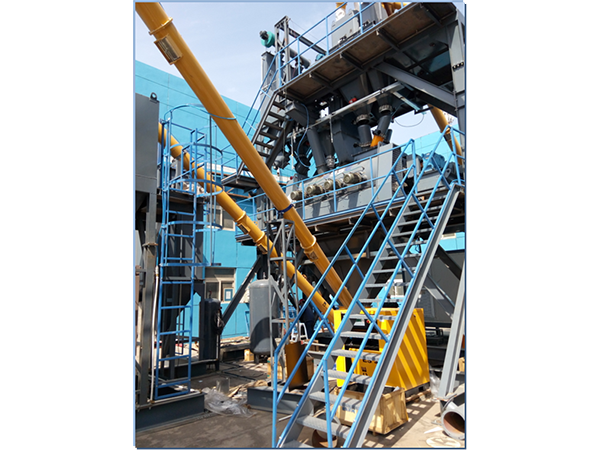

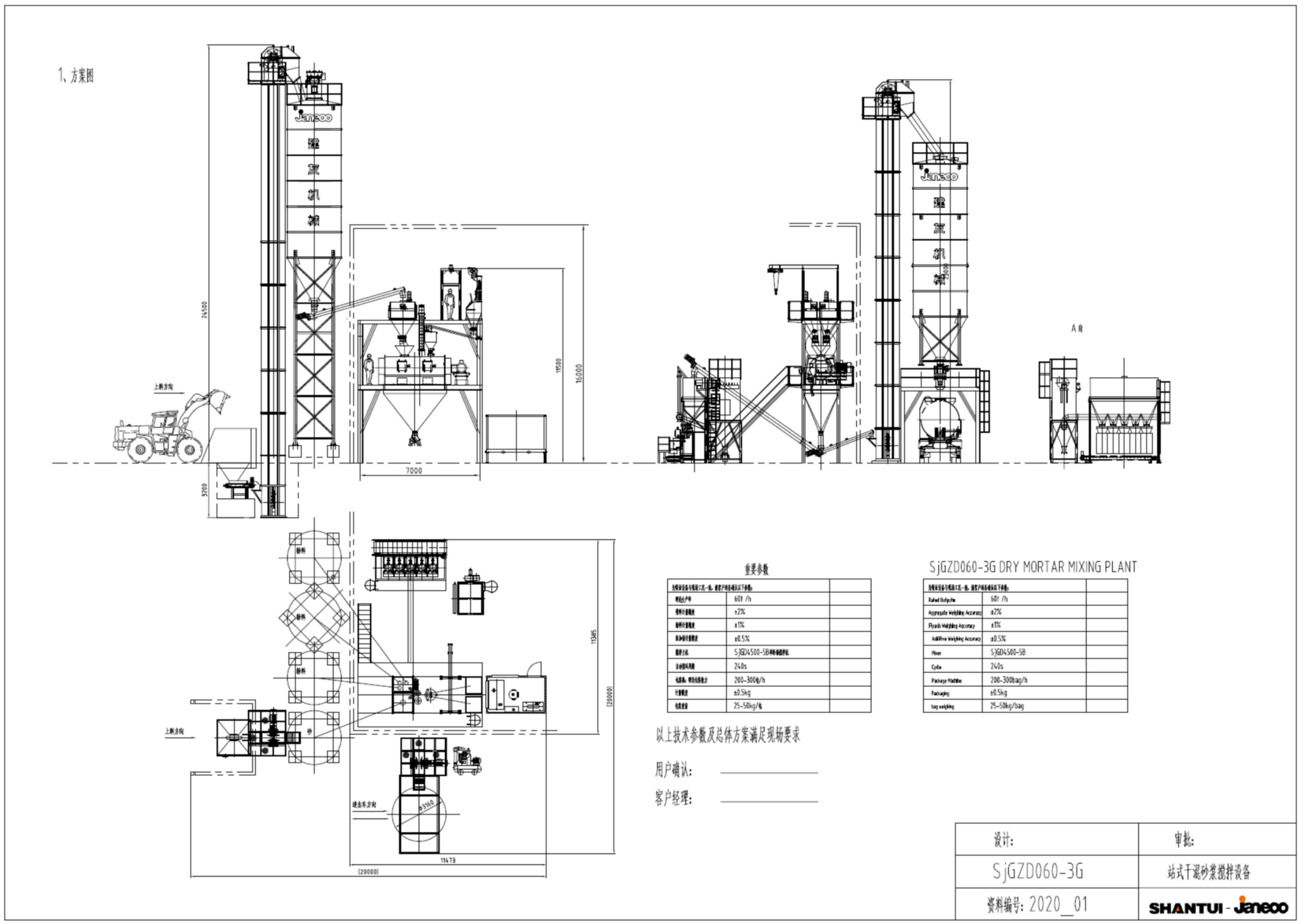

SjGZD060-3G Station Type Dry Motar batching plant

Main spesifikaasjes

1.main spesifikaasjes

Teoretyske produktiviteit 60t / h

Mixer SjGD4500-5B

aggregaten mjitten krektens 2

Cement mjitten krektens 1%

Additive mjitnauwkeurigheid 0,5%

Sânsilo folume 72m3

Cement silo folume 72m3

Additive silo folume 0,5m3

Packing kapasiteit 200-300bags / h / set

Totale krêft 140kW (útsein silo- en schroeftransporteurs)

1.Sânsilo

| Folume | 72m3 |

| Diameter | 3,2m |

2.Cement silo

| Folume | 72m3 |

| Diameter | 3,2m |

3.Additive silo

| Folume | 0,5m3 |

4.Sand batching screw conveyor

| skroef diameter | 323 mm |

| kapasiteit | 35m3/h |

5.Sand batching screw conveyor

| skroef diameter | 273 mm |

| kapasiteit | 50m3/h |

6.aggregate mjitten hopper

| type | elektroanyske skaal |

| Max wearde | 3000 kg |

| Krektens | ± 2% |

7.Cement mjitten hopper

| type | elektroanyske skaal |

| Max wearde | 2500 kg |

| Krektens | ± 1% |

8.Additive mjithopper

| type | elektroanyske skaal |

| Max wearde | 150 kg |

| Krektens | ± 0,5% |

9. Mixer

| Mixer | SjGD4500-5B |

| Motor macht | 90 kw |

| Blade macht | 4x5,5kw |

10.Packing masine

| Packing kapasiteit | 200-300 bags / h / set |

| Elke tas gewicht | 25 ~ 50 kg |

| Krektens | ±0,5 kg |

11.pneumatyske systeem

| lucht compressor macht | 30 kW |

| druk | 0,75 MPa |

12.dust removal systeem

| Filter | 60m2 |

| Krêft | 7,5 kW |

20.elektrysk systeem

It systeem wurdt oandreaun troch AC 380V en 50Hz trije-fase fjouwer (fiif) wire systeem.

21.Computer kontrôle

Hânlieding en automatysk

22.cycle tiid

| Auto | 240s |

Beskriuwing

SjGZD060-3G stasjon type droege moarmer mixing apparatuer is in soarte fan apparatuer ûntwurpen en ûntwikkele troch ús bedriuw neffens de ferlykbere produkten yn it bûtenlân en kombinearre mei de eigentlike situaasje yn China.It is geskikt foar it mingen gewoane droege moarmer en spesjale droege moarmer.

De wichtichste apparatuer oannimt stasjon struktuer, ynklusyf 1 sân bin (72m3 / stik), 3 poeder bin (72m3 / stik), en 2 additive bin (0.5m3 / stik). It sân wurdt opheft troch in emmer masine, it poeder wurdt ferfierd nei de poedersilo troch in bulk tank truck, en de twa additieven wurde opheft nei de additive silo laach troch in elektrysk opheffen apparaat en set yn 'e additive silo manuell. , mjitting accuracy is heech, lytse error.The kontrôle systeem oannimt hantlieding en automatyske kontrôle. It systeem hat perfekte sels-locking en inter-locking funksjes te garandearjen krekte en betroubere wurking fan it systeem, en hat mienskiplike fout detection en alarm funksjes.

Konfiguraasje

| 一, Haadgebou | ||||

| Nee. | Beskriuwing | Ûnderdiel | Oantal | Opmerking |

| 1 | skeal | 1 |

| |

| weach skaal Max.3000kg | 1 | |||

| druk load sel | 3 | |||

| load sel ferbinende dielen | 3 | |||

| (DN300) pneumatyske flinterklep (DN300) | 2 | |||

| MVE60/3 vibrator MVE60/3 | 1 | |||

| cement weighing skaal Max.2500kg | 1 | |||

| druk load sel | 3 | |||

| load sel ferbinende dielen | 3 | |||

| pneumatyske flinterklep (DN250) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 2 | additive opslach silo | 1 |

| |

| additieven bin (folume: 0.5m3) | 2 | |||

| Ferset twist-aksje-yndikator | 2 | |||

| hânmjittich flinterklep (DN250) | 2 | |||

| transverter | 1 | |||

| vibrator MVE60/3 | 2 | |||

| 3 | additive weachskaal | 1 |

| |

| Max.gewicht skaal 150 kg | 1 | |||

| load sel | 3 | |||

| pneumatyske flinterklep (DN200) | 1 | |||

| pneumatyske flinterklep Ø250 | 1 | |||

| MVE60/3 vibrator MVE60/3 | 1 | |||

| 4 | additive hoisting apparaten | 1 |

| |

| frame | 1 | |||

| 1000Kg Elektryske hoist 1000KG | 1 | |||

| 5 | 手工投料装置Hânliedingapparaat | 1 |

| |

| hânmjittich feeding bin | 1 | |||

| pneumatyske flinterklep (DN200) | 1 | |||

| 6 | mingsysteem |

|

| |

| stypjende basis (Q235 Steel struktuer) | 1 | |||

| Tank body (16Mn Steel struktuer) | 1 | |||

| tagongspoarte (16Mn Steel struktuer) | 2 | |||

| ischarge gate (16Mn Steel struktuer) | 1 | |||

| 90KW mingapparaten | 1 | |||

| mingen skacht en skacht ein | 1 | |||

| discharge apparaten | 1 | |||

| Sampling apparaat | 1 | |||

| sampling buis lichem (struktuer komponinten) | 1 | |||

| sampling silinder | 1 | |||

| hânmjittich rjochtingsklep | 1 | |||

| auxiliary mixing apparaten | 4 | |||

| Fly cutter apparaat | 4 | |||

| 7 | klear hopper | 1 |

| |

| hopper body (16Mn) | 1 | |||

| Ferset twist-aksje-yndikator | 1 | |||

| vibrator MVE60/3 | 1 | |||

| hânmjittich flinterklep (DN250) | 2 | |||

| 8 | Products ferpakking | 1 |

| |

| klear hoppe | 1 | |||

| Frame | 1 | |||

| Ferset twist-aksje-yndikator | 2 | |||

| vibrator MVE60/3 | 1 | |||

| Valve pocket ferpakking masine | 1 | |||

| Riem (L=4500m,B=650mm,2.2kw) | 1 | |||

| 9 | stof-removal apparaat | 1 |

| |

| 7.5KW Pulse blaasfilter | 1 | |||

| Stof removal piping | 1 | |||

| 10 |

| 1 |

| |

| 30KWair kompressor 30KW | 1 | |||

| AFF22C-10D | 1 | |||

| 1m3 | 1 | |||

| Gas-way joint | 1 | |||

| 11 | kontrôle systeem | 1 |

| |

| kompjûter | 1 | |||

| elektryske komponinten | 1 | |||

| LCD monitor | 1 | |||

| 打印机 printer | 1 | |||

| UPS | 1 | |||

| kontrôle konsole | 1 | |||

| kabinet | 1 | |||

| wire, kabel en brêge. | 1 | |||

| 12 | kontrôle Keamer | 1 |

| |

| Kontrôle keamer ramt | 1 | |||

| Control keamer decorate | 1 | |||

| Ferljochting en switch | 1 | |||

| airconditioning 1P | 1 | |||

| 13 | stielen struktuer | 1 |

| |

| perron | 1 | |||

| ljedder | 1 | |||

| lâning skonken | 1 | |||

| screw conveyer | ||||

| 14 | φ323X5500mm 18.5KW screw conveyer | 1 |

| |

| 15 | φ323X3000mm 15KW screw conveyer | 1 |

| |

| 16 | φ219X5000mm 7.5KW screw conveyer | 1 |

| |

| 17 | φ219X7000mm 7.5KW screw conveyer | 1 |

| |

| 18 | φ219X9000mm 9.2KW screw conveyer | 1 |

| |

| 19 | Ø114x1500mm, schroeftransporteur | 2 |

| |

| 20 | Ø323-9000 schroeftransporteur | 1 |

| |

| 21 | SNC100 silo | Diameter: 3.2m, V: 72m3 | 3 |

|

| Arch break apparaat | 3 |

| ||

| Hânlieding (DN300) | 3 |

| ||

| Rotary nivo meter | 6 |

| ||

| Silo top feilich klep | 3 |

| ||

| Silo top pols werom flush filter | 3 |

| ||

| 22 | SNC100 silo | Diameter: 3.2m, V: 72m3 | 1 |

|

| Hânlieding (DN300) | 1 |

| ||

| Rotary lever meter | 2 |

| ||

| Silo top pols werom flush filter | 1 |

| ||

| 23 | SNC100 silo | Diameter: 3.2m, V: 72m3 | 1 |

|

| Arch break apparaat | 1 |

| ||

| Hânlieding (DN300) | 1 |

| ||

| Rotary nivo meter | 2 |

| ||

| Silo top pols werom flush filter | 1 |

| ||

| stipe skonk, silo lichem en accessoires | 1 |

| ||

| 24 | Baklift 60m3/h | 2 |

| |

| Lift (24m, 11kw) | ||||

| Ljedders en ûnderhâld platfoarm | ||||

| feeding en lossen chute | ||||

| 25 | pneumatyske klep | 1 |

| |

| stypjende basis | 1 | |||

| silinder | 1 | |||

| elektromagnetyske klep | 1 | |||

| 26 | Bulk mortel loader | Bulk mortel loader | 1 |

|

| 27 | hopper | 1 |

| |

| buchet | 1 | |||

| (B=650mm, 2.2kW) Riem | 1 | |||