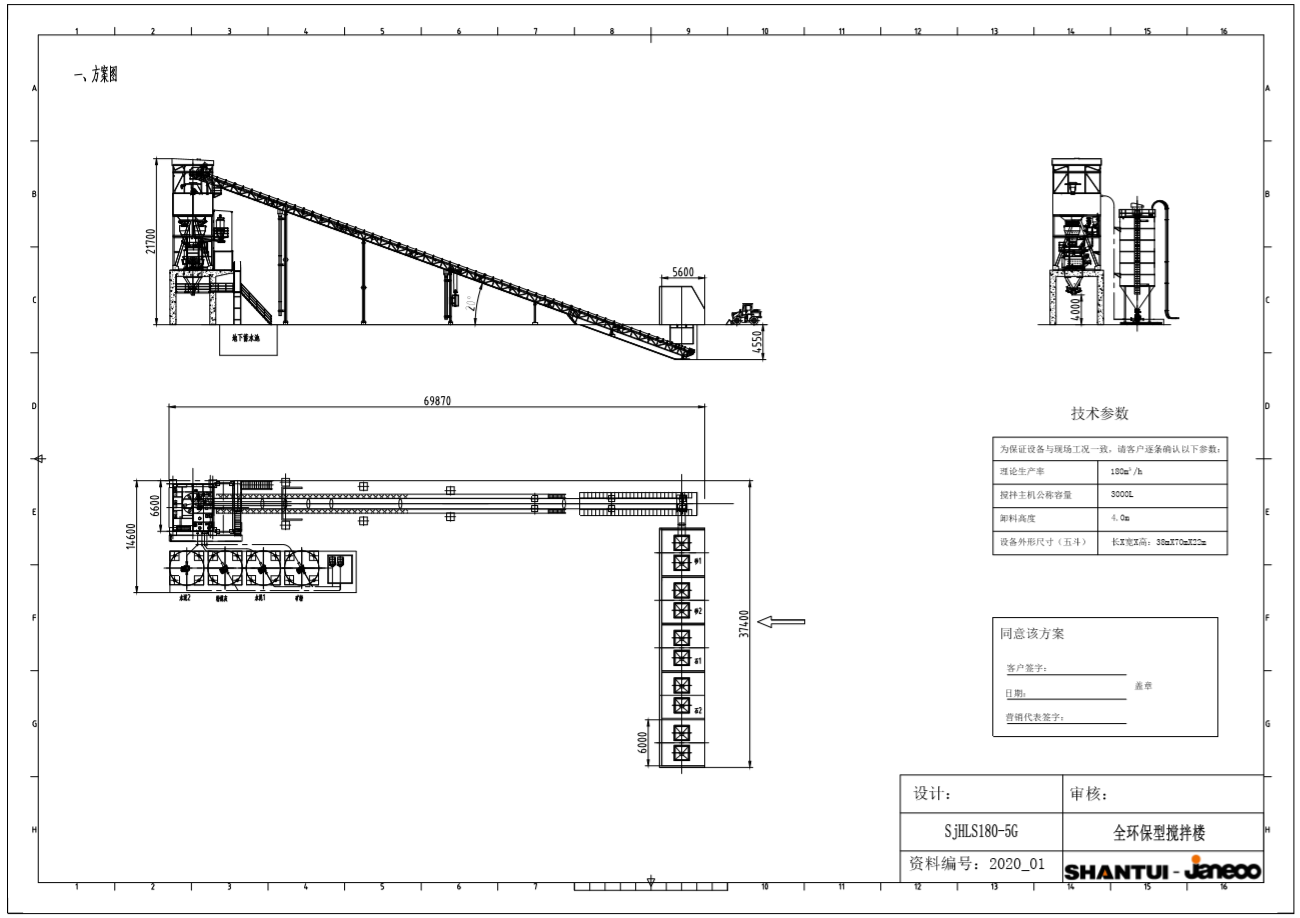

SjHZS180G G rige miljeufreonlik type

SjHZS180G foardielen

1. Skaaimerken:

1.1.Double-as en fjouwer-screw effisjinte mingen host;

1.2.multi-point monitoring, real-time monitoring fan

de kwaliteit fan beton.

1.3.De eigentlike produksje effisjinsje fan 160m3 / h

is folle heger as de yndustry gemiddelde

130m3 / h effisjinsje.

Applikaasje: It is oanpast oan ready-mix beton produksje.

Beskriuwing:

SjHZS180-5G Concrete mingen plant oannimt modulêre struktuer, dat hat de skaaimerken fan hege effisjinsje, enerzjybesparring en miljeubeskerming.

1.1 Modulêr ûntwerp

Yn dizze apparatuer is modularisaasje realisearre, dy't kinne wurde ferdield yn ienheden foar ferfier en opheft en kombineare foar ynstallaasje, wat ienfâldich en fluch is.

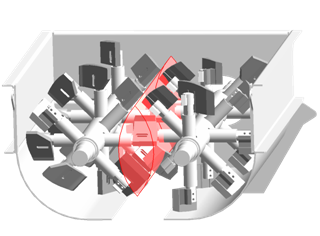

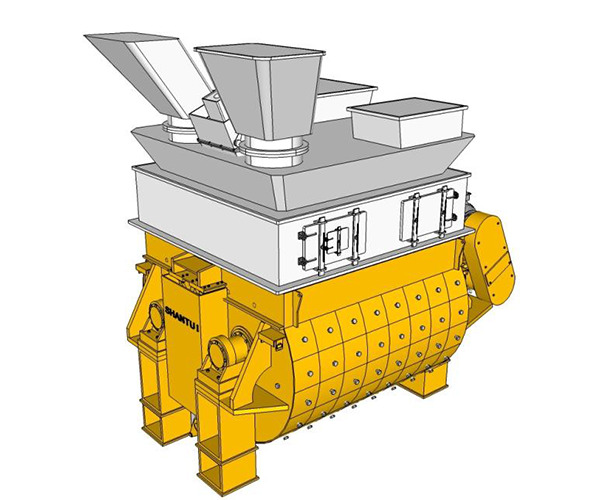

2.1 SjJS3000G mixer mei hege sterkte, hege trochstreaming en eksplosive krêft

2.2 Unike cutting effekt:

2.3 Unike luchtdichtingsapparaat

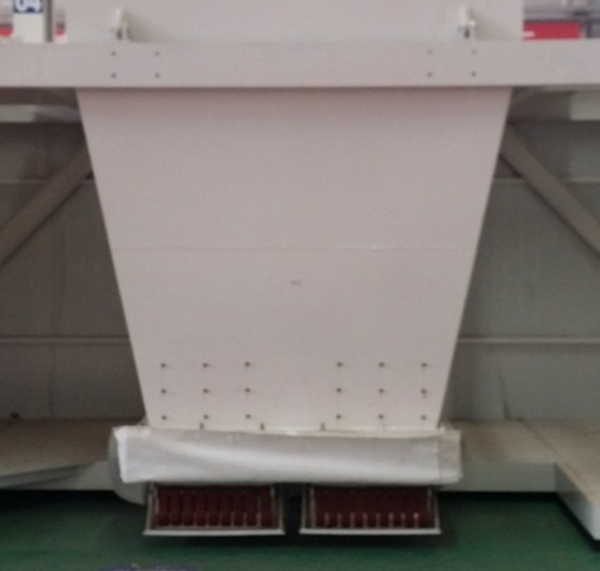

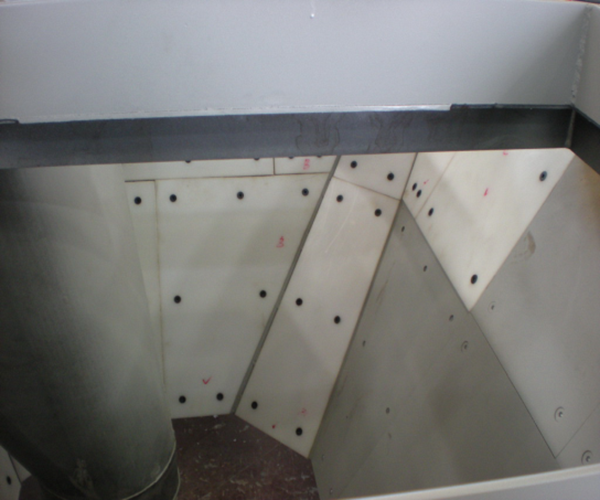

3.1 Unike 6m grutte-kapasiteit klear produkt hopper:

4.1 Elts weagjen systeem hat fyn oanpassing en kompensaasje apparaat, hege weighing presyzje

5, Ready-mix feedapparaat

Konstruksje gefallen:

Konfiguraasje

| 1, Haadkonfiguraasje | |||||

| Beskriuwing | Ûnderdiel | Spesifikaasje | Oantal | Ienheid | Oarsprong |

| 1 Aggregate batching masine (grûntype) | Sân hoppers (grûntype) | 50 m3 | 2 | set | Sensor:TOLEDO;Parts:SMC; Krektens: ±2%; |

| Stone hoppers (grûntype) | 50 m3 | 2 | set | ||

| Weagjen systeem | Maksimum 3000 kg | 4 | set | ||

| Sensor | SBT-2 | 12 | Pc. | ||

| Útlaad poarte | 4 | set | |||

| Flat conveying systeem | 400m3/h,B = 1000 mm | 1 | set | ||

| Driving systeem | 1 | set | |||

| Belt masine struktuer | 1 | set | |||

| Feiligens apparaat | 1 | set | |||

| 2 Aggregates conveying systeem | Neigeande conveying systeem | 400m3/h ,B = 1000 mm | 1 | set | |

| Driving systeem | 1 | set | |||

| Belt masine struktuer | 1 | set | |||

| Whole Seal decoration | 1 | set | |||

| Feiligens apparaat | 1 | set | |||

| Chute wask apparaat | 1 | set | |||

| Skjin apparaat | 1 | set | |||

| 3 Haadgebou | Main stielen struktuer | Afvoerhoogte 4m | 1 | set | Parts:SMC; Filter:WAM; |

| Haadfilter | 44 m2 | 1 | set | ||

| Riemfilter | 6 m2 | 1 | set | ||

| Main dekoraasje | (50 mm) | 1 | set | ||

| Betonbak | V:6 m3 | 1 | set | ||

| Monitoring apparaat | 1 | set | |||

| Vibrator | MVE200-3 | 1 | set | ||

| Underhâld platfoarm | 1 | set | |||

| Midden opslach hopper | 1 | set | |||

| Weagjen sensor | SBT-3 | 1 | Pc. | ||

| vibrator | MVE200-3 | 1 | set | ||

| Mixer | JS3000G(V:3m3) | 1 | Pc. | ||

| Driving systeem | 2×55 kW | 2 | set | ||

| Silinder | CB-140B-450 | 2 | Pc. | ||

| Feed apparaat | 1 | set | |||

| Wetterpomp | 1 | set | |||

| Monitoring apparaat | 1 | set | |||

| Cement weachsysteem | Maksimum 1800 kg | 1 | Pc. | Sensor:TOLEDO;Valve:WAM; Krektens: ±1%; | |

| Weagjen sensor | SBT-2 | 3 | Pc. | ||

| Valve | V1FS250 | 1 | Pc. | ||

| Vibrator | S30 | 1 | Pc. | ||

| Poeder gewicht systeem | Maksimum 900 kg | 1 | Pc. | ||

| Weagjen sensor | SBT-2 | 3 | Pc. | ||

| Valve | V1FS250 | 1 | Pc. | ||

| Vibrator | S30 | 1 | Pc. | ||

| Mine weachsysteem | Maksimum 500 kg | 1 | Pc. | ||

| Weagjen sensor | SBT-2 | 3 | Pc. | ||

| Valve | V1FS250 | 1 | Pc. | ||

| Vibrator | S30 | 1 | Pc. | ||

| Wetterweinsysteem | Maksimum 800 kg | 1 | Pc. | Sensor:TOLEDO;Krektens: ±1%; | |

| Weagjen sensor | TSC-1000 | 3 | Pc. | ||

| Valve | 1 | Pc. | |||

| Additive weachsysteem | Maksimum 100 kg | 1 | Pc. | (Patent item)Sensor:TOLEDO; Krektens: ±1% | |

| Sensor | TSC-300 | 1 | Pc. | ||

| Valve | 1 | Pc. | |||

| Anti-lek apparaat | 1 | set | |||

| 4 Wetter oanfier systeem | Valve | Elk 1 | set | ||

| Pipen (ynter) | 1 | set | |||

| Wetterpomp | 1 | Pc. | |||

| Pool en pipen (bûten) | Troch klant | 1 | set | ||

| 5 Liquid additive systeem | Pipes | Elk 1 | set | ||

| Pipes (Inter) | 2 | set | |||

| Additive tank en pipes(bûtenste) | Mei pomp,10Tizeren tank | 2 | set | ||

| 6 Pneumatyske systeem | Air compressor | 15 kW | 1 | Pc. | Parts:SMC;Droger:SMC; |

| Opslach tank | 1m3 +0,3m3 | 1 | set | ||

| Droger | 1 | set | |||

| Piip | 1 | set | |||

| Parts | 1 | set | |||

| 7 Kontrôle systeem | Kontrôle Keamer | 1 | set | Haadkomponinten: Schneider; PLC: Siemens ; Monitor:SAMSUNG;

| |

| Software | Bosure | 1 | set | ||

| Operaasje tafel | 1 | set | |||

| Kontrôle tafel | 1 | set | |||

| Monitor | 22" | 1 | Pc. | ||

| Printer | EPSON | 1 | Pc. | ||

| Klimaatregeler | 1.5 | 1 | Pc. | ||

| Kompjûter | 1 | Pc. | |||

| Monitoring systeem | 4 kamera | 1 | set | ||

| Monitor | 22" | 1 | set | ||

| Ljocht systeem | 1 | set | |||

| Kommunikaasje | 4 kamera | 1 | set | ||

| 2, Opsjoneel | |||||

| 1 Cement silo | SC300 | V:300T(V: 225m3,semint) | 5 | set | Cement 3 set,poeder 1 set,myn poeder 1 set |

| SC100 | V:100T(V:73m3,semint) | 1 | set | Swelling additive | |

| Accessories | Filter, nivometer, bôgebrekker ensfh. | 6 | set | Filter: Pulse back flush typeValve:WAM. | |

| Platfoarm op de top |

| 1 | set | Ferbining fan alle silo's | |

| 2 Screw conveyor | Foar cement | φ323 | 3 | set | WAM |

| Foar poeder | φ273 | 1 | set | WAM | |

| Foar myn poeder | φ219 | 2 | set | WAM | |